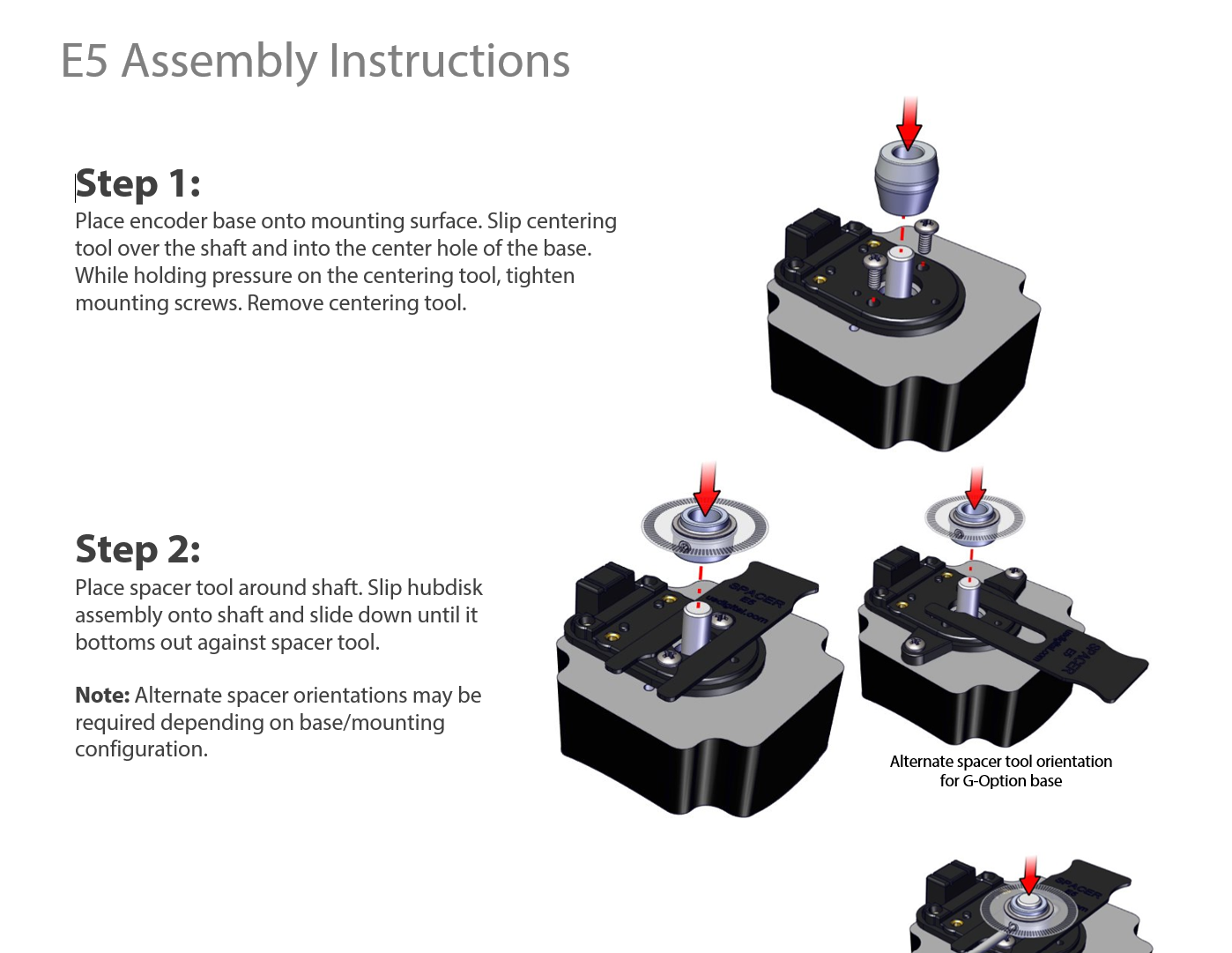

1. Centering Tool

Part #: CTOOL - (Shaft Diameter)

This reusable tool centers the shaft within the encoder base during assembly. It is required for the proper functioning of the encoder..

2. Hex Tool

Part #: HEXD-050

Hex driver, 0.050" flat-to-flat for #3-48 or #4-48 set screws. Included with -B or -1 packaging options for encoder quantities of 10 or more.

Part #: HEXW-050

Hex wrench, 0.050" flat-to-flat for #3-48 or #4-48 set screws. Included with -B or -1 packaging options for encoder quantities of 9 or less. Included with -3 packaging option for all order quantities.

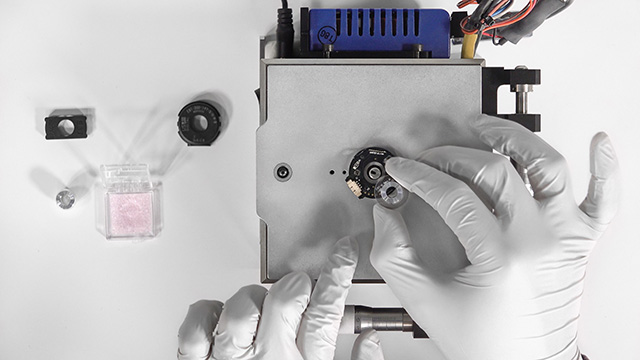

3. Spacer Tool

Part #: SPACER-E5

This reusable tool sets the proper spacing between the disk and sensor during assembly. It is required for the proper functioning of the encoder.

4. Screws

Part #: SCREW-080-250-PH

Description: Pan Head, Philips #0-80 UNF x 1/4"

Use: Base Mounting

Quantity Required: 3

Screws are not included

Part #: SCREW-256-250-PH

Description: Pan Head, Philips #2-56 UNC x 1/4"

Use: Base Mounting

Quantity Required: 2

Screws are not included

Part #: SCREW-440-250-PH

Description: Pan Head, Philips #4-40 UNC x 1/4"

Use: Base Mounting

Quantity Required: 2

Screws are not included

Part #: SCREW-440-500-PH

Description: Pan Head, Phillips #4-40 UNC x 1/2"

Use: Module Mounting

Quantity Required: 2

Screws are included

Part #: SCREW-440-625-FH

Description: Flat Head, Phillips 4-40 UNC x 5/8"

Use: Cover Mounting

Quantity Required: 2

Screws are included

Part #: SCREW-448-063-SS

Description: Socket Head Set Screw, 4-48 UNC x 1/16"

Use: Hub/Disk Mounting for 5/16" - 10mm Bore

Quantity Required: 1

Screw is included

Part #: SCREW-448-125-SS

Description: Socket Head Set Screw, 4-48 UNC x 1/8"

Use: Hub/Disk Mounting for 2mm - 1/4" Bore

Quantity Required: 1

Screw is included