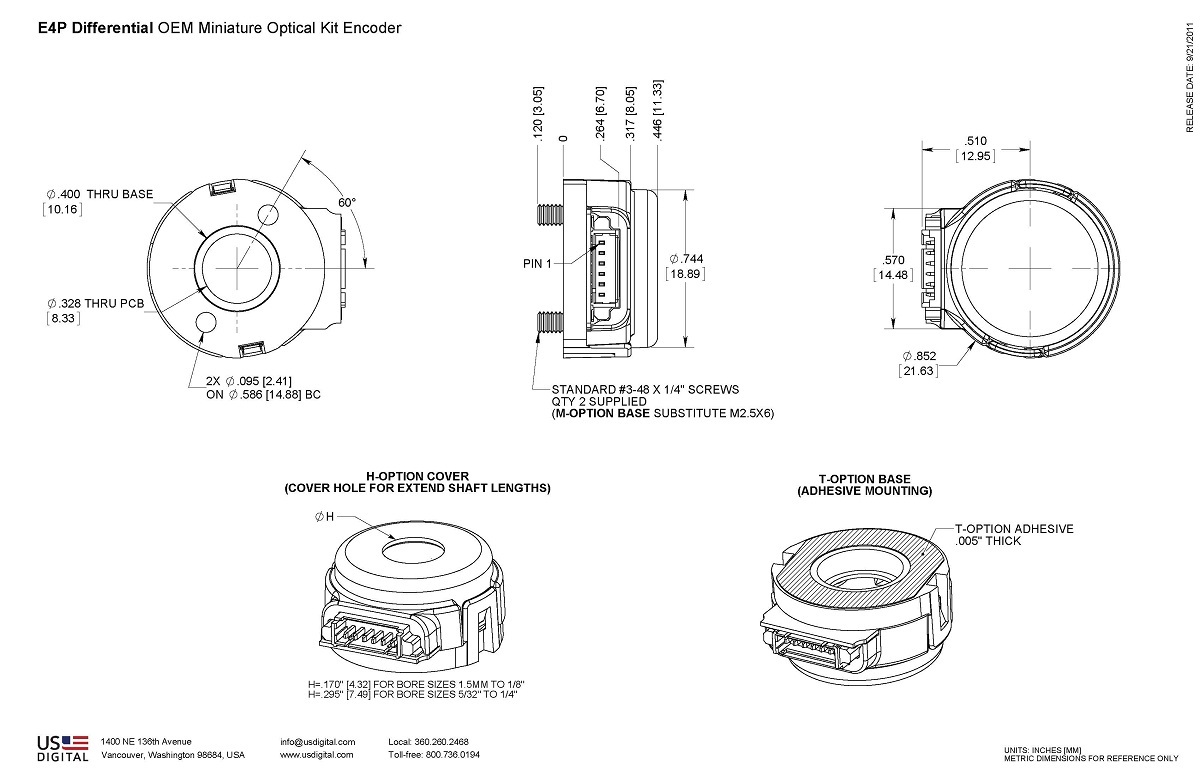

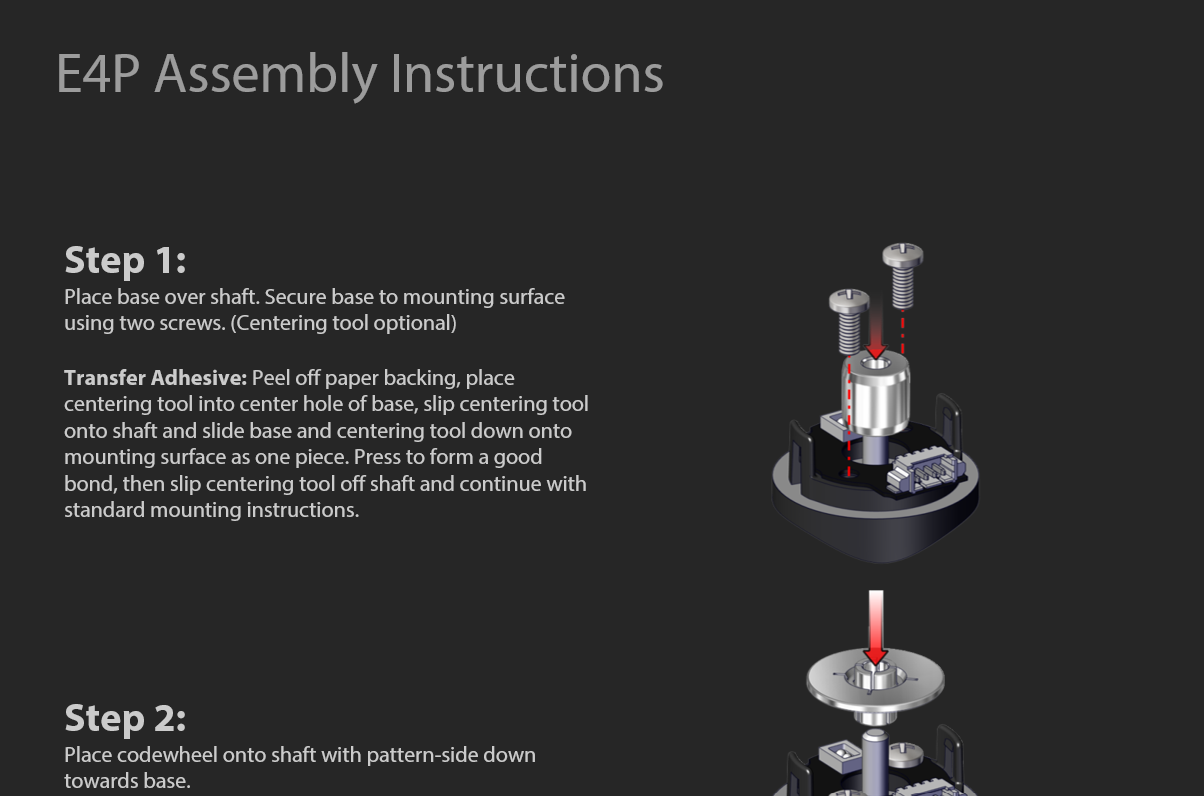

E4P OEM MINIATURE OPTICAL KIT ENCODER

E4P Features

- Miniature size

- Push-on hub - spring loaded collet design

- Minimum shaft length of .375 in.

- Fits shaft diameters of .079 in. to .250 in.

- Accepts +/-.020 in. Axial shaft play

- Off-axis mounting tolerance of .010 in.

- 100 to 360 cycles per revolution (CPR)

- 400 to 1,440 pulses per revolution (PPR)

- Single +5V supply

See more info below

Configure the E4P