Blog

Discover how US Digital simplifies processes for its customers and employees, with a focus on their ongoing success. How can we contribute to your success? Read More »

Published in News > Blog

Discover how US Digital simplifies processes for its customers and employees, with a focus on their ongoing success. How can we contribute to your success? Read More »

Published in News > Blog

Discover how US Digital simplifies processes for its customers and employees, with a focus on their ongoing success. How can we contribute to your success? Read More »

Published in News > Blog

What is a motor encoder? How do encoders work on a motor? What does an encoder do on a motor? Get these and more questions answered here. Read More »

Published in News > Blog

This is a case study of how we went the extra mile for one of our customers. That is what we do. Put us to the test. How can we help you? Read More »

Published in News > Blog

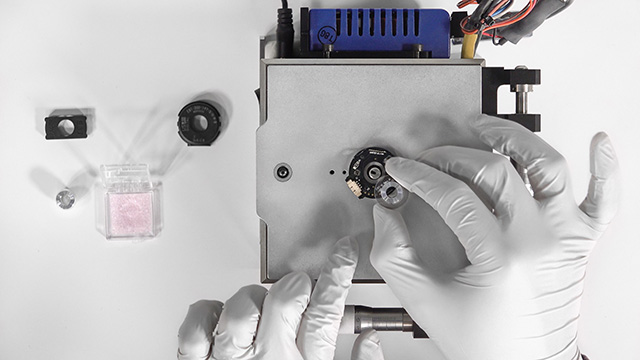

Need to clean one of our optical encoders. This article will provide you good options--and tell you what not to do so the encoder will continue to work. Read More »

Published in News > Blog

When one of our customers needed an encoder modified to work for their application, we turned around a custom variant for them within a matter of weeks. Read More »

Published in News > Blog

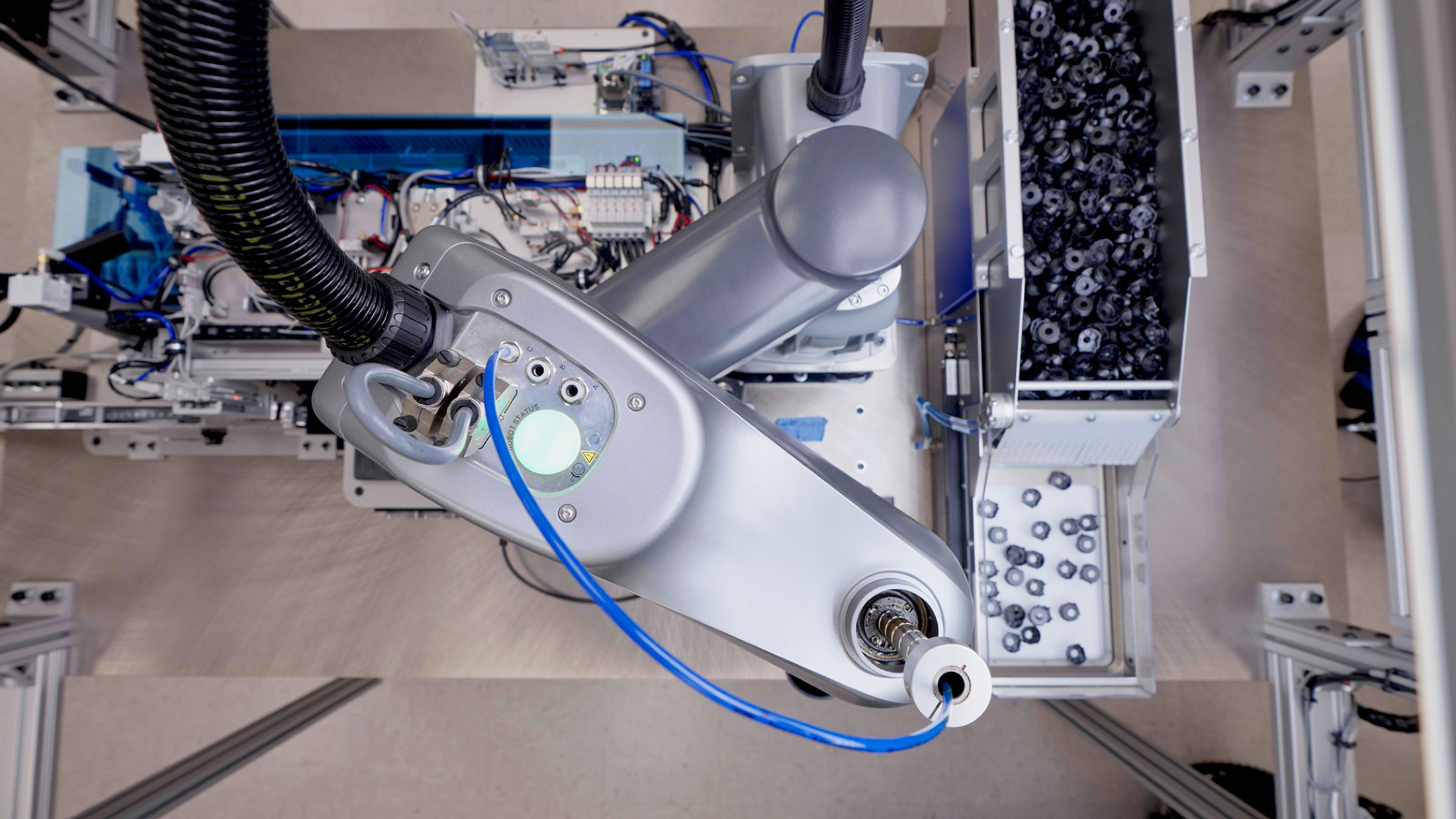

When one of our Mechanical Engineers was looking to automate an assembly process, his design included a robot with absolute positioning capability. Read More »

Published in News > Blog

We put a serial number on every one of our EM1 and EM2 modules and a manufacturer order number on encoder covers to track when individual components were made. Read More »

Published in News > Blog

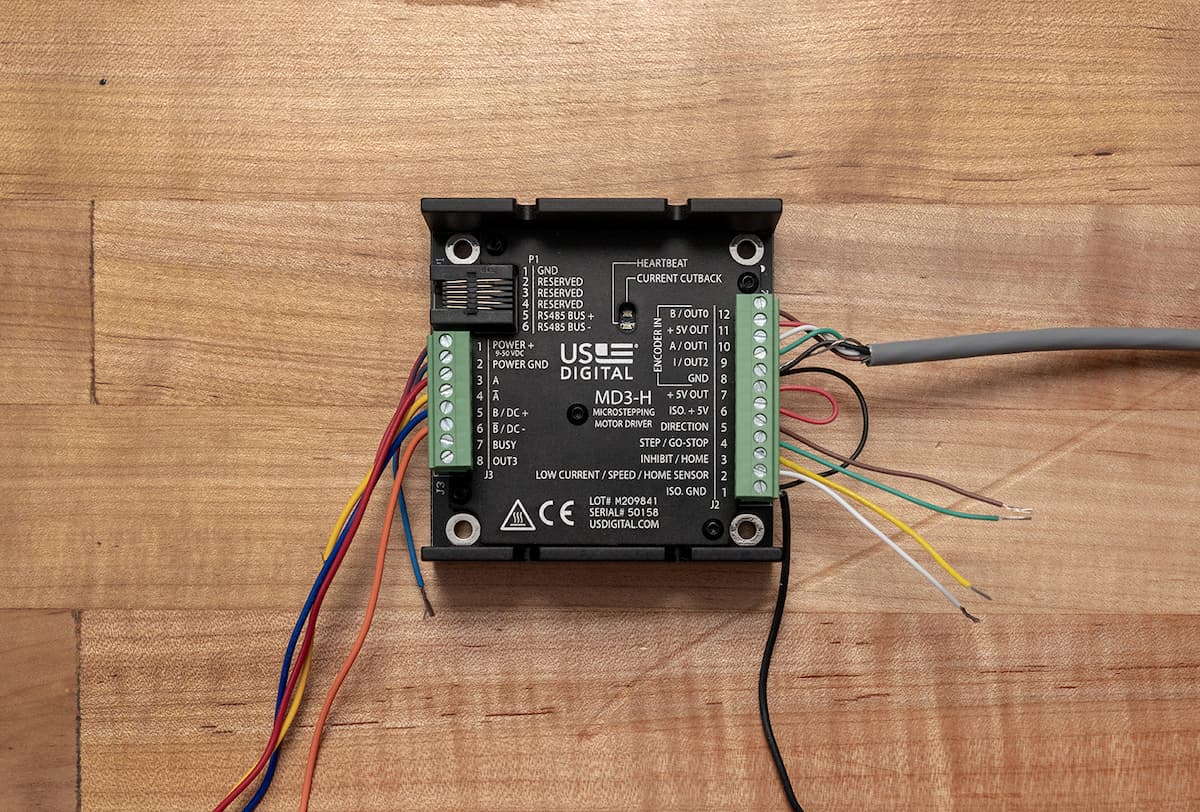

US Digital's MD3 motor driver for stepper motors is a great solution for many in motion control. Check out this blog-video explaining configuration. Read More »

Published in News > Blog

More in News

Company Links

- About Us

- Careers

- Contact Details

- Distributors

- Environmental Stewardship

- Legal

- Quality and Compliance

- Videos

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.