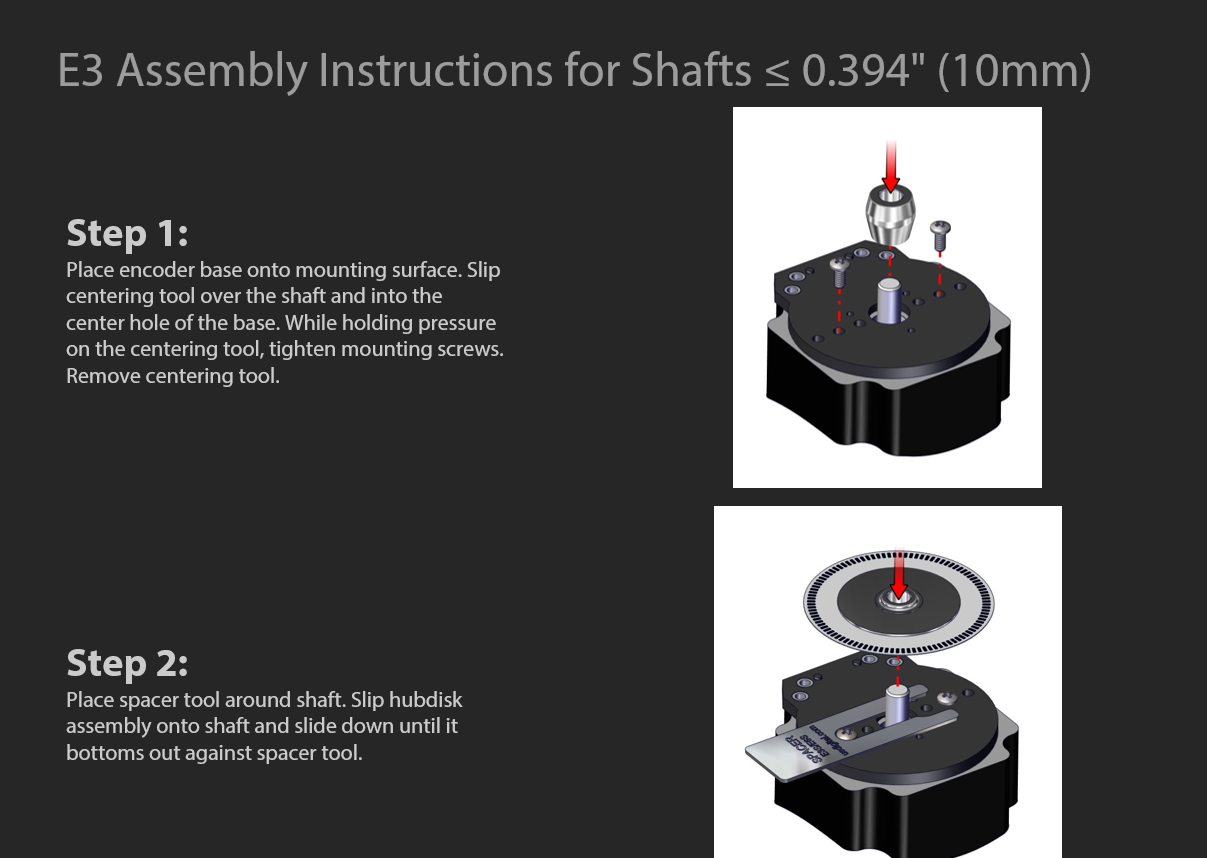

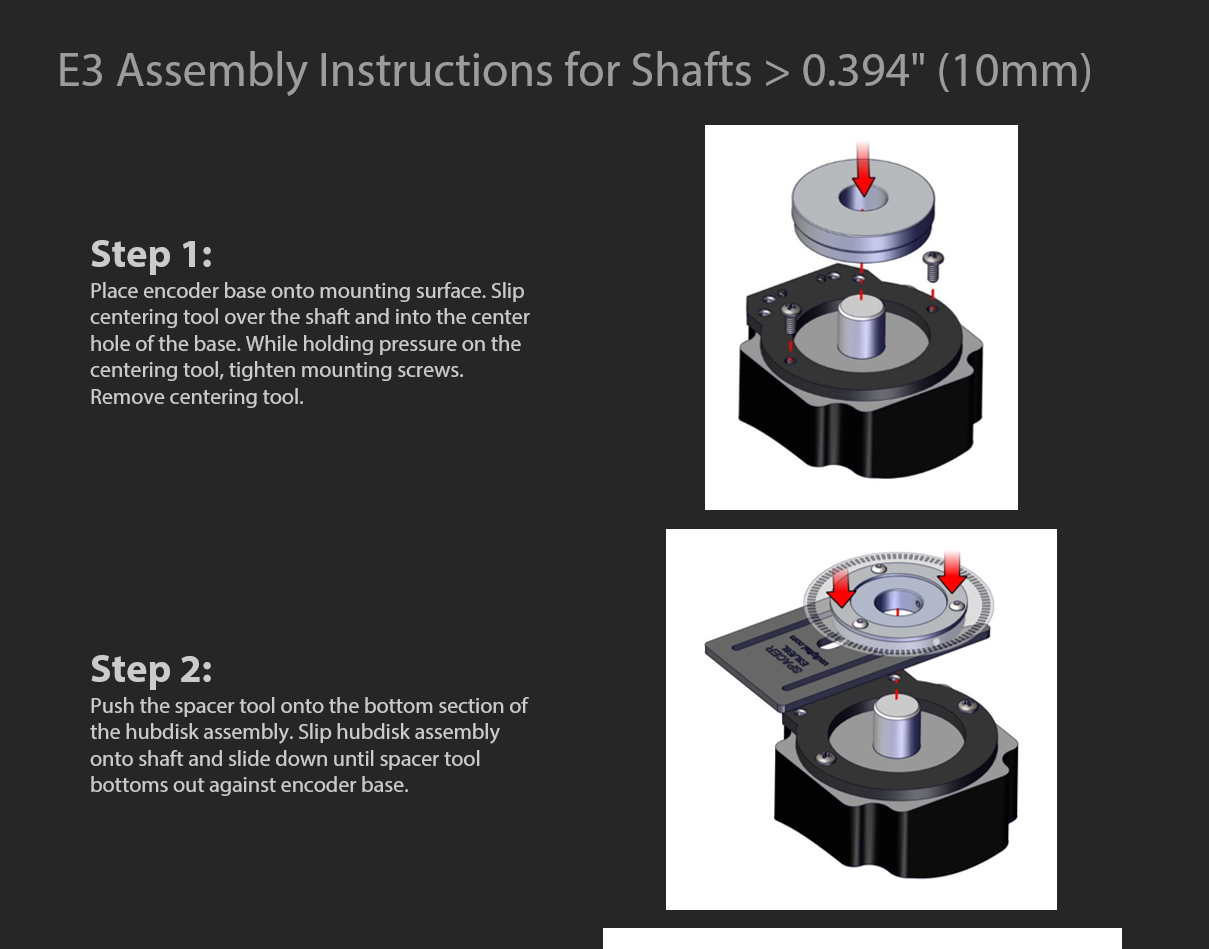

1. Centering Tool

Part #: CTOOL - (Shaft Diameter)

This reusable tool centers the shaft within the encoder base during assembly. It is required for the proper functioning of the encoder.

2. Hex Tool

Part #: HEXD-050

Hex driver, 0.050" flat-to-flat for #3-48 or #4-48 set screws. Included with -B or -1 packaging options for order quantities of 10 or more.

Part #: HEXW-050

Hex wrench, 0.050" flat-to-flat for #3-48 or #4-48 set screws. Included with -B or -1 packaging options for order quantities of 9 or less. Included with -3 packaging option for all order quantities.

3. Spacer Tool

This reusable tool sets the proper spacing between the disk and sensor during assembly. It is required for the proper functioning of the encoder.

Part #: SPACER-E3S

Description: For shafts ≤ 0.394"

Part #: SPACER-E3L

Description: For shafts 12mm - 1"

4. Screws

Part #: SCREW-080-250-PH

Description: Pan Head, Philips #0-80 UNF x 1/4"

Use: Base Mounting

Quantity Required: 3

Screws are not included

Part #: SCREW-256-250-PH

Description: Pan Head, Philips #2-56 UNC x 1/4"

Use: Base Mounting

Quantity Required: 2

Screws are not included

Part #: SCREW-348-125-SS

Description: Socket Head Set Screw, 3-48 UNC x 1/8"

Use: Hub/Disk Mounting for 12mm - 1" Bore

Quantity Required: 2

Screws are included

Part #: SCREW-440-250-PH

Description: Pan Head, Philips #4-40 UNC x 1/4"

Use: Base Mounting

Quantity Required: 2

Screws are not included

Part #: SCREW-440-500-PH

Description: Pan Head, Phillips #4-40 UNC x 1/2"

Use: Module Mounting

Quantity Required: 2

Screws are included

Part #: SCREW-440-625-FH

Description: Flat Head, Phillips 4-40 UNC x 5/8"

Use: Cover Mounting

Quantity Required: 2

Screws are included

Part #: SCREW-448-063-SS

Description: Socket Head Set Screw, 4-48 UNC x 1/16"

Use: Hub/Disk Mounting for 5/16" - 10mm Bore

Quantity Required: 1

Screw is included

Part #: SCREW-448-125-SS

Description: Socket Head Set Screw, 4-48 UNC x 1/8"

Use: Hub/Disk Mounting for 2mm - 1/4" Bore

Quantity Required: 1

Screw is included