Glossary of Terms

-

A

-

Absolute Encoder

An Absolute Encoder is an encoder that provides a unique output for each resolvable position even after a power cycle. Unlike incremental encoders which provide an output...Read more...

Back to Top -

Accuracy

Encoder Accuracy is the difference between the target position and the actual position. It is typically specified in degrees, arcminutes or arcseconds. US Digital has a white...Read more...

Back to Top

C

-

Channel

A Channel is an electrical output signal from an incremental encoder. Channels are designated A and B for the two quadrature outputs and I or Z for the index output....Read more...

Back to Top -

Cycle

A Cycle refers to one complete four-state quadrature cycle. One quadrature cycle is generated by one line and one window called a line pair on the encoder disk. Each cycle is...Read more...

Back to Top -

Cycle Error

Cycle Error is the difference between the target (theoretical) position of the shaft and the actual position indicated by the encoder cycle count....Read more...

Back to Top -

CPR (Cycles Per Revolution)

CPR is the number of full quadrature cycles per full shaft revolution (360 mechanical degrees). A 200 CPR encoder can provide 200, 400, or 800 positions per revolution depending...Read more...

Back to Top

D

-

Differential Output

Differential Output is an output employing a complementary channel for the standard encoder output channels. Each complementary channel provides -5VDC simultaneously as the...Read more...

Back to Top -

Disk

A disk is the round mylar material used by US Digital on which is placed an evenly spaced pattern of windows and lines. When that pattern passes between an LED and detector the...Read more...

Back to Top -

Duty Jitter

E

-

Eccentricity Error

Eccentricity Error is the measurement in the error of a rotary encoder caused by an eccentricity in the mounting of the encoder disk....Read more...

Back to Top -

Electrical Degree (°e)

An Electrical Degree (°e) is 1/360 of an electrical cycle. Electrical degrees are used in encoder specifications to indicate the width of a pulse, the Rise and Fall times of a...Read more...

Back to Top -

Encoder

An Encoder is an electro-mechanical device that translates physical motion into an electrical signal. That data can be used by a control device to determine speed, acceleration,...Read more...

Back to Top -

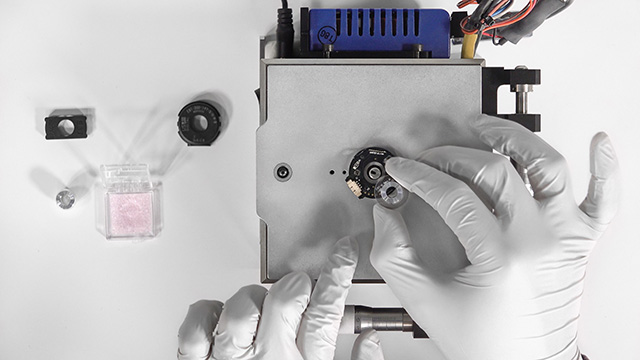

Encoder Module

An Encoder Module is an electronic component made by US Digital which incorporates an LED and detector through which a medium with evenly spaced lines and windows passes to...Read more...

Back to Top

F

-

Frequency

Frequency is the number of cycles per second which can be read by an encoder. Each encoder is rated at specific frequencies based on how fast the encoder can read the information...Read more...

Back to Top

H

-

Homing Cycle

A Homing Cycle is the movement of an incremental encoder to find its index. This is helpful upon power-up as without an index and homing cycle, the location within the encoder’s...Read more...

Back to Top -

HubDisk

A HubDisk assembly consisting of an aluminum hub and an optical encoder disk....Read more...

Back to Top

I

-

Inclinometer

An Inclinometer is a device that reports the angle of an object with respect to gravity. Also known as a "tilt sensor."...Read more...

Back to Top -

Incremental Encoder

An Incremental Encoder is an encoder that provides information via a waveform output as to the movement of a shaft. It does not provide positional information but that can be...Read more...

Back to Top -

Index (Ch. I)

The Index is a unique location on an encoder disk or linear strip used as a reference point. The index output is provided via a third channel on quadrature encoders and is often...Read more...

Back to Top -

Interpolation

Interpolation is the internal multiplication of a signal in an encoder providing a higher resolution than the native disk resolution. This is executed via the internal circuitry...Read more...

Back to Top -

IP (Ingress Protection) Ratings

IP Ratings identify the ability of an enclosure to resist intrusion. Common examples are IP64 and IP69. The first digit indicates the protection against the ingress of solids...Read more...

Back to Top

L

-

Line Count

Line Count is the number of equally spaced lines on a linear strip or disk. The space between each line is referred to as a window. Each line/window pair is the basis for...Read more...

Back to Top -

Line Driver

A Line Driver is a circuit designed to increase the maximum recommended cable length for an encoder, and/or to add immunity from electrical noise or interference on the signal...Read more...

Back to Top -

Linear Strip

A Linear Strip is the mylar material used by US Digital on which is placed an evenly spaced pattern of windows and lines. When that pattern passes between an LED and detector the...Read more...

Back to Top

M

-

Magnetic Encoder

A Magnetic Encoder is an encoder that uses a magnetic code wheel to provide an output based on the speed and direction of the shaft. A magnetic sensor in the encoder detects the...Read more...

Back to Top -

Moment of Inertia

The Moment of Inertia is the point at which the rotational force being applied to a shaft equals the resistance to change in angular velocity....Read more...

Back to Top

N

-

Noise

Noise is any unwanted electrical signal that can potentially interfere with a desired signal. The potential sources for electrical noise are numerous. Electrical noise can be...Read more...

Back to Top

O

-

Open Collector Output

Open Collector Output is an output that allows the user to set the voltage level of the output signal by installing a pull-up resistor between the output channel and a power...Read more...

Back to Top -

Optical Encoder

An Optical Encoder is an encoder using a light source, detector and interrupting medium to provide an output based on the speed and direction of the lines on that medium. Optical...Read more...

Back to Top -

Output Waveforms

Output Waveforms are the relationship of the output signals to each other, normally shown in a diagram as below. This shows the sequence of all output signals including channels...Read more...

Back to Top

P

-

Phase

A Phase the delay in time or degrees between the rising edge of channel A and the rising edge of channel B. Also defined as the delay between the center of the high state on...Read more...

Back to Top -

Phase Jitter

Phase jitter is the variation between the rising edges of channel A and channel B from one cycle to another....Read more...

Back to Top -

Phase Relationship

Phase Relationship identifies which channel (A or B) leads (goes high first) the other channel based on the rotation of the shaft. The perspective from which the relationship is...Read more...

Back to Top -

Phased Array

A Phased Array is a pattern of photodiodes used on US Digital encoders to detect several lines and windows simultaneously. The array averages these pairs to provide an output...Read more...

Back to Top -

Position Error

-

Pseudo-Absolute Encoder

A Pseudo-Absolute Encoder is an incremental encoder used as an absolute encoder on single turn applications which use a homing cycle. This requires that the media (disk or linear...Read more...

Back to Top -

PPR (Pulses Per Revolution)

PPR is the term US Digital uses to refer to the number of pulses after 4x quadrature multiplication. US Digital uses CPR to identify the before quadrature resolution of an...Read more...

Back to Top

Q

-

Quadrature

Quadrature is the most common digital incremental encoder output. It uses two channels (typically referred to as channels A and B) which are offset from each other by 90...Read more...

Back to Top

R

-

Resolution

Resolution relates to the quantity of increments an encoder has in one rotation (for a rotary encoder). An encoder disk has a specified number of lines on it providing for a...Read more...

Back to Top -

Revolution

Revolution is one complete rotation of the encoder shaft, 360 mechanical degrees....Read more...

Back to Top

S

-

Shaft Axial Play

Shaft Axial Play is the movement of the shaft in the axial direction. US Digital states the maximum shaft axial play in thousandths of an inch....Read more...

Back to Top -

Shaft Loading aka Radial Load

Shaft Loading is the specification used on shafted encoders and refers to the force applied perpendicular to the shaft. An increase in the amount of force on a shaft will...Read more...

Back to Top -

Shaft Runout

Shaft Runout is the deviation of a shaft from true circular rotation. This can be caused by a bent shaft or a loose bearing. US Digital’s datasheets for encoder kits have a...Read more...

Back to Top -

Single-Ended Output

Single-Ended Output is the most basic kind of output on an encoder. Each channel only has one wire which provides a train of pulses alternating between 0 to 5 volts in...Read more...

Back to Top -

Stiction

Stiction is a combination of the words stick and friction. Stiction exists when the static (starting) friction exceeds the dynamic (moving) friction. An example of stiction would...Read more...

Back to Top -

Symmetry

Symmetry is the relationship of the on time to the off time (x,y) for any encoder channel. This specification is shown on the datasheet in electrical degrees for the EM1 and the...Read more...

Back to Top

T

-

TIR (Total Indicated Runout)

TIR is a measurement of shaft runout—deviation of a shaft from true circular rotation....Read more...

Back to Top