When do you need an absolute encoder?

What type of applications call for an absolute encoder vs incremental? Let’s get into it.

Incremental encoders report relative movement. If that encoder has an Index, it can report shaft position in relation to the Index once the Index is found. Absolute encoders can report exact shaft position whenever they are powered. (If you’re looking for more information on the difference between absolute encoders and incremental ones, we wrote an entire blog post on the subject.)

If your application requires that you know the actual orientation of the shaft following any power cycle before movement is made, you’re going to need an absolute encoder. Why would that be? In some cases, even the slightest movement to find an Index could be harmful to the process being performed, the product being handled or possibly hazardous to the automated equipment. In other cases, your system doesn’t have the ability to find a home position.

Example use case: Using an absolute encoder to determine reel tension

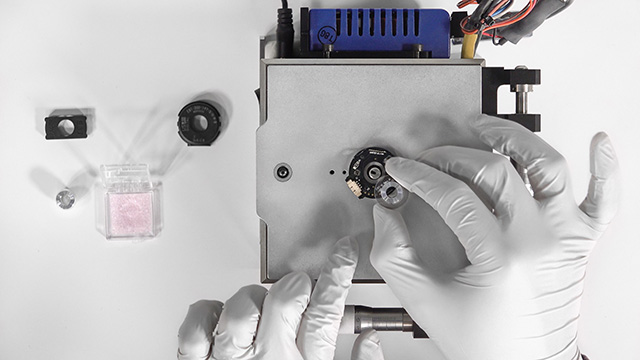

One of our engineers used our MAE3 absolute encoder to trigger a drive motor that unwinds a reel of stamped lead frames into an injection molding machine in our plant. How does it work?

A pivoting arm rests on the bare lead frame entering the molding machine (see photo above). The absolute encoder is attached to the axis of that pivot arm. When the arm hangs down vertically there is no tension and the absolute angle is set to zero.

Approximately every 30 seconds overmolded parts exit the mold as the next section of bare lead frame enters. The molding machine pulls in more of the bare lead frame causing tension to the incoming reel and the pivot arm to rise. The encoder is used by the system to quantify the absolute angular position with respect to the set zero position.

Whenever the pivot arm is raised to a predetermined angle range indicating tension, the system unspools more of the bare lead frame. If the arm is outside of the tension angular range, feeding stops.

Maintaining a proper feed rate is necessary to make sure that the lead frame is not being stretched or bent before being overmolded thus preventing damage to the equipment.

In this case our engineer used an absolute encoder because the arm itself isn’t motor driven and angles detected are with reference to a fixed zero angle. The absolute encoder mitigates the need to zero or return to a home position if there was a loss of power.

If your application is susceptible to the issues above, you’re going to want an absolute encoder. If not, you could use an incremental encoder with Index. In that case, when the encoder loses power, you’d just need the system to perform a home cycle to find Index again and then it could report its position in relationship to that Index.

Side note: You may even consider an incremental encoder with multiple Indices, which could limit the amount of turning the shaft would need to do to reach a known Index position. To learn more, be sure to reach out to us and ask about our custom solutions.

More in News

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.