| PARAMETER |

SLEEVE BUSHING |

BALL BEARING |

| Max. Acceleration |

250000 rad/sec² |

250000 rad/sec² |

| Max. Shaft Speed (mechanical) |

100 rpm (1) |

10000 rpm (1) |

| Max. Shaft Torque |

0.5 in-oz (D-option)

0.3 in-oz (N-option) |

0.05 in-oz (B-option) |

| Max. Shaft Loading |

2 lbs. dynamic

20 lbs. static |

1 lb. |

| Bearing Life |

> 1000000 revolutions |

L10 = (19.3/Fr)³ *

Where L10 = bearing life in millions of revs, and

Fr = radial shaft loading in pounds |

Weight

Single-ended (S option)

Differential (D option)

High-Voltage, Open-Collector (H, C option) |

1.92 oz.

2.00 oz.

2.00 oz. |

1.78 oz.

1.86 oz.

1.86 oz. |

| Max. Shaft Runout |

0.0015 in. T.I.R. |

0.0015 in. T.I.R. |

| Max. Panel Nut Tightening Torque |

20 in-lbs |

20 in-lbs |

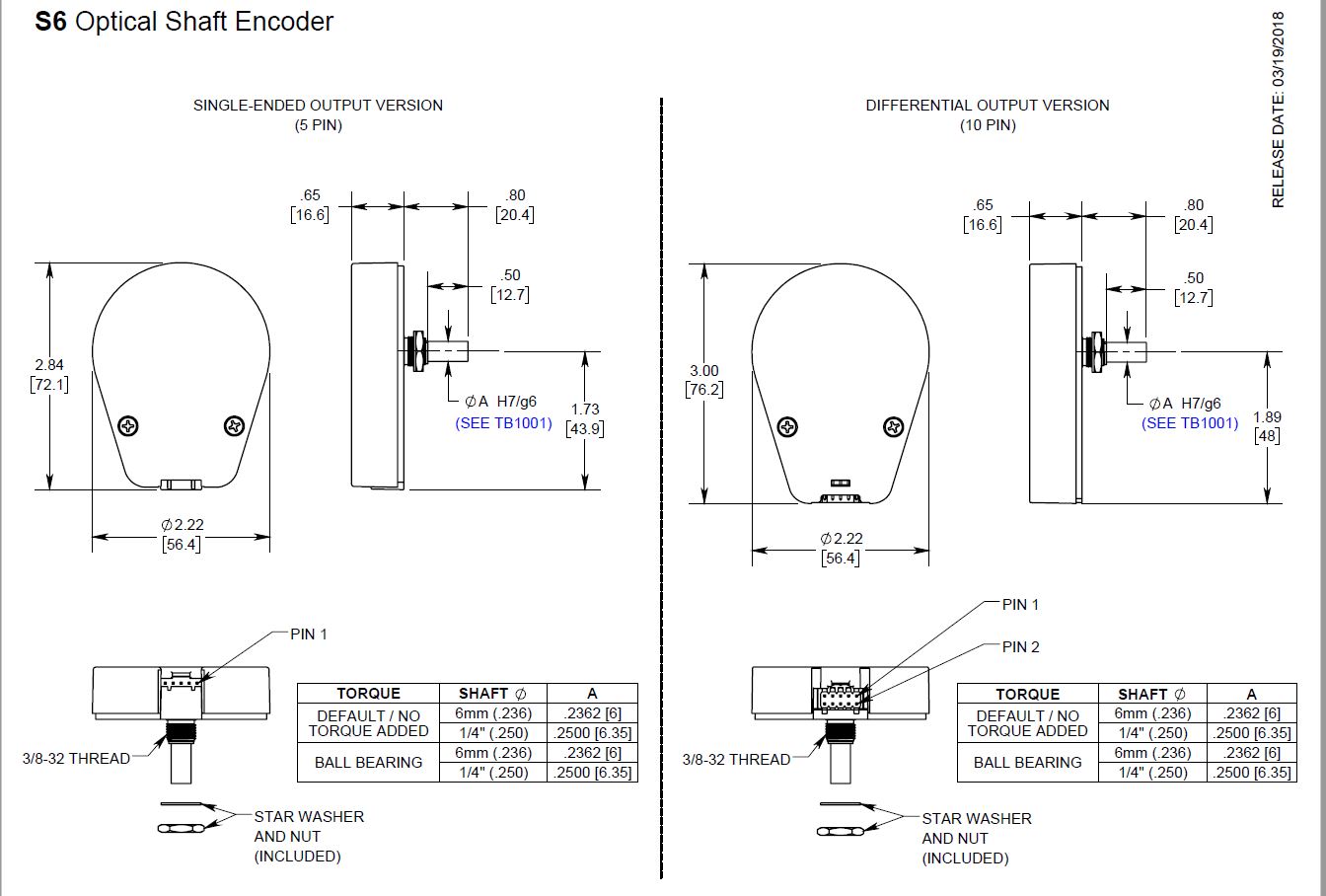

| Technical Bulletin TB1001 - Shaft and Bore Tolerances |

Download |

* Only valid with negligible axial shaft loading.

(1) The maximum speed due to electrical considerations is dependent on the CPR. See the EM1 and EM2 product pages.