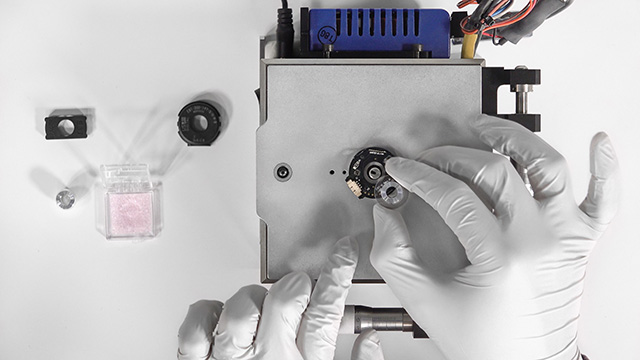

HD25 Industrial Rugged Metal Optical Encoder

HD25 Features

- NEMA size 25 package

- Anodized black aluminum housing

- 64 to 10,000 cycles per revolution (CPR)

- 256 to 40,000 pulses per revolution (PPR)

- 2-channel quadrature output with optional index

- Single-ended or differential outputs

- Sealed IP65 option

See more info below

Configure the HD25