How Are Encoders Used on Pumps in the Medical Industry?

How do you attach an encoder to a liquid? Encoders usually attach to a part of the system that moves—and in a pump, the part that moves is a liquid! How do you attach an encoder to that?

In actual practice, you don't. Every pump has a mechanism that moves a fluid. You attach the encoder to that mechanism. If a motor drives the mechanism, for example, you can mount the encoder to the motor shaft—and information reported by the encoder can be used to control fluid moved by the pump. You can improve pump performance when an encoder is part of the system.

WHAT CAN ENCODERS MEASURE ON PUMPS?

In any pump with an encoder, there is usually a relationship between the mechanical system's basic motion (revolution, stroke etc.) and the amount of fluid that is pumped with each motion. The pump's job is to perform the motion; the encoder's job is to report the motion, so that the pump's controller can calculate quantities like volume or speed.

Volume Metering - Sometimes the important quantity is the total volume moved, and speed of delivery is less important. When you pump gasoline at a gas station, it might take 3 minutes to fill up the tank, or it might take 5 minutes. The time isn't critical; you're not paying by the minute, you're paying by the gallon or liter. The key measurement you're interested in will be the volume—the pump has to get that right, and an encoder on the pump can help ensure accurate volume metering.

Speed Metering - Sometimes a pump's job is to keep a liquid moving at an optimum speed, and the precise volume might not be important. In a water treatment plant, for example, pumps move fluid slurries long distances. Irregularities in the speed of flow can cause unwanted vibrations and even dangerous pressure buildup in the pipe. When a pump is commanded by a controller to accelerate or decelerate to maintain a constant flow, an encoder can report the change and help verify desired speed.

Speed/Volume Combinations - Sometimes a pump has to deliver an exact volume at a specific speed. This is common in the healthcare setting, where encoders are used on pumps that administer medicines at a precisely controlled flow rate.

In the sections below, we'll look at three examples from the life sciences and medical industries, where encoders are used on pumps in hospitals, clinics, research laboratories and by individuals at home.

AUTOMATED PIPETTORS

The IVEK Corporation makes automated pipettors and displacement pumps for original equipment manufacturers (OEMs). Their AutoPipettor is a good place to start for understanding encoders on pumps. What's an AutoPipettor? It's similar to an eyedropper—but it's automated.

Scaled up versions of eyedroppers are used in laboratories, pharmacies and drug manufacturing facilities. The tube is called a pipette; various sizes are used, ranging in length from an inch to more than a foot. The part that creates pressure to move liquid in or out of the pipette—the equivalent of the eyedropper's bulb—is called the pipettor.

Because the process of pipetting might be performed thousands of times each day in busy labs and manufacturing facilities, OEMs have developed automated machinery for the task. Automated pipettors can draw fluid into pipettes at the touch of a button or computer command.

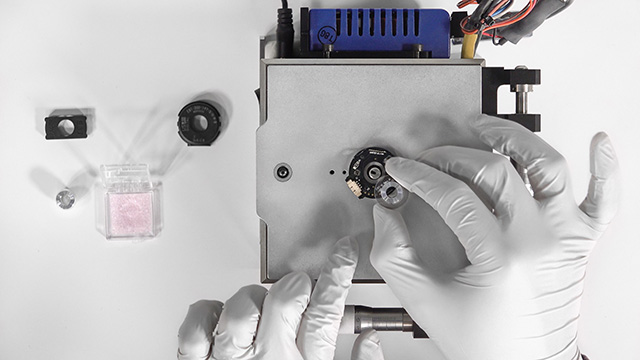

In her right hand, the technician in the photograph below holds an automated pipettor which is attached to a pipette.

Pipettors equipped with encoders can move the required amount of fluid automatically, without the need for a technician to visually check the levels. This means they can be used in automated production lines, either individually or ganged together into multiple units.

IVEK's AutoPipettor uses a close-fitting ceramic piston and cylinder set. When the piston is drawn into the cylinder, suction is created which moves fluid into a pipette. When the piston moves in the other direction, the pressure created dispenses the liquid. A linear actuator driven by a stepper motor is the mechanism that moves the piston.

You can see an encoder mounted to the stepper motor if you click on the AutoPipettor link.

AUTO-INJECTORS

An auto-injector delivers a measured dose of a drug. Many are spring-loaded syringes intended to be self-administered for quick, one-time use, such as the EpiPen® Epinephrine Auto-Injector.

For long term drug therapy patients, a more sophisticated auto-injector is required. Large-volume injections require long delivery times; high viscosity drugs require extra force to deliver the drug; insulin might require differing flow rates, based on blood sugar levels. Motorized auto-injectors can meet these requirements, while being portable and discreet for patients who use them in public.

To administer drugs, auto-injectors can use a combination of electric motors, gearboxes, and linear motion assemblies. When the mechanism is equipped with an encoder, the auto-injector can precisely deliver medicine at an accurately controlled rate of flow.

INFUSION PUMPS

In a hospital setting, many different medications and fluids may be given to a patient. Some can be given within a few seconds: a nurse can inject the contents of a syringe under the skin, or through an IV (Intravenous Tube). However, some medications take hours to administer. To free up nursing staff so they can attend to other duties, a pump with an encoder may be used—particularly when a large volume of medicine or a slow injection speed is involved.

Infusion pumps accomplish the task of delivering medications automatically. Of the many types available, peristaltic pumps are often selected. Inside these pumps, one or more rollers mounted on a rotor push against flexible tubing. Fluid is delivered into one end of the flexible tube, typically by gravity feed. With each pass of a roller, a set amount of fluid is pushed down the tube and through the IV.

Instead of rollers, a linear peristaltic pump uses a series of mechanical fingers driven by a camshaft; the fingers sequentially press against the tubing to pump liquid through the tube. Both types of pumps—rotary and linear—are used for infusion.

When the motor that drives the rotor or camshaft is equipped with an encoder, the pump's internal control system can receive position reports from the encoder. Since a known amount of fluid is delivered with each pass of a roller, speed of flow can be verified from the encoder reports.

With the precise control an encoder provides, medical staff can program the pump to deliver fluids at a constant rate or a variable rate; large volumes quickly, or small volumes over many hours; and many other flow rate choices.

More in News

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.