Press Releases

US Digital is announcing a new output configuration that enables many of its popular incremental encoders to accept power up to 30VDC without external adapters. Read More »

Published 9/20/2023 in News > Press Releases

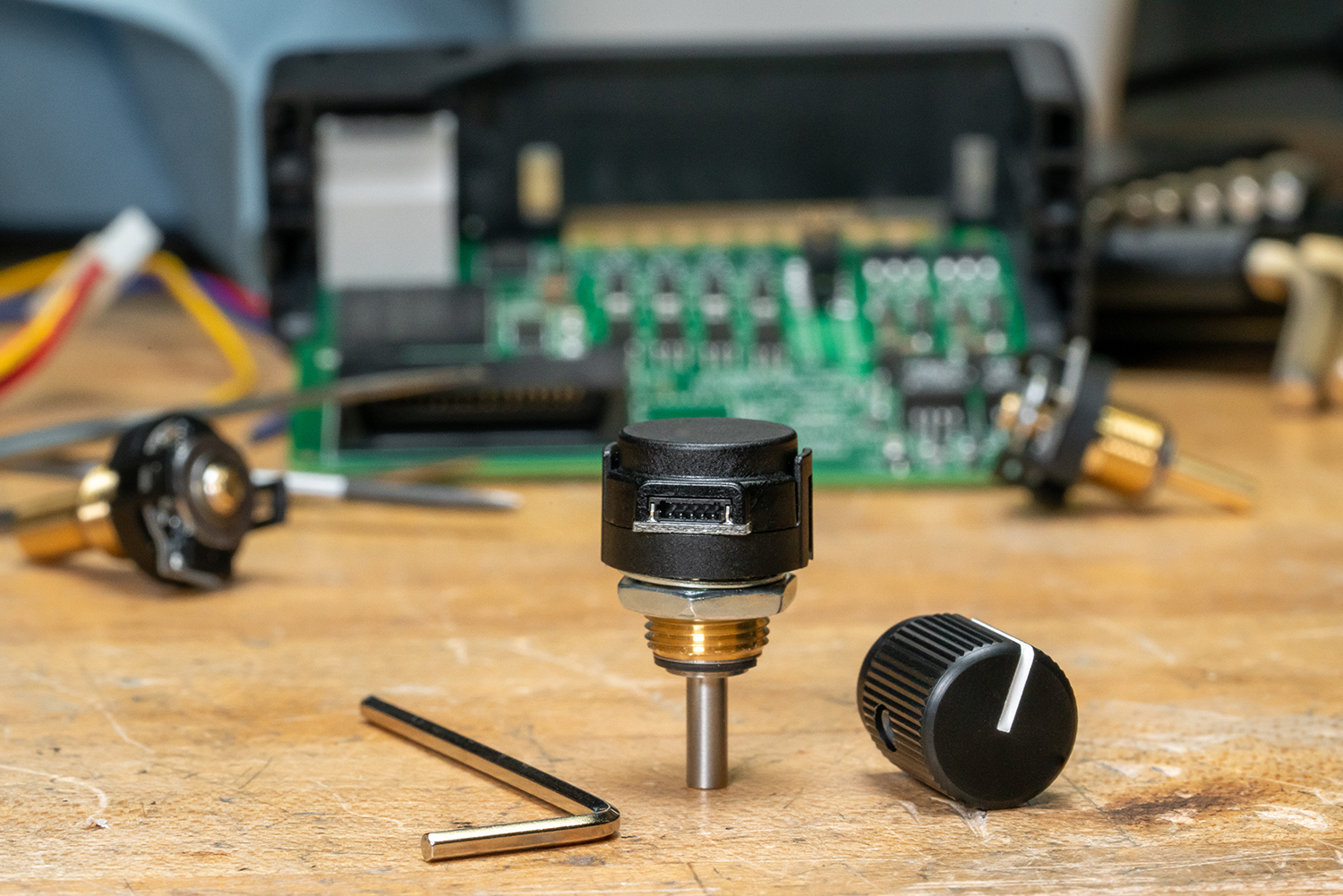

US Digital on January 17, 2022, announced it was expanding its line of miniature encoders with a new shafted encoder, the S16. Read More »

Published 1/18/2022 in News > Press Releases

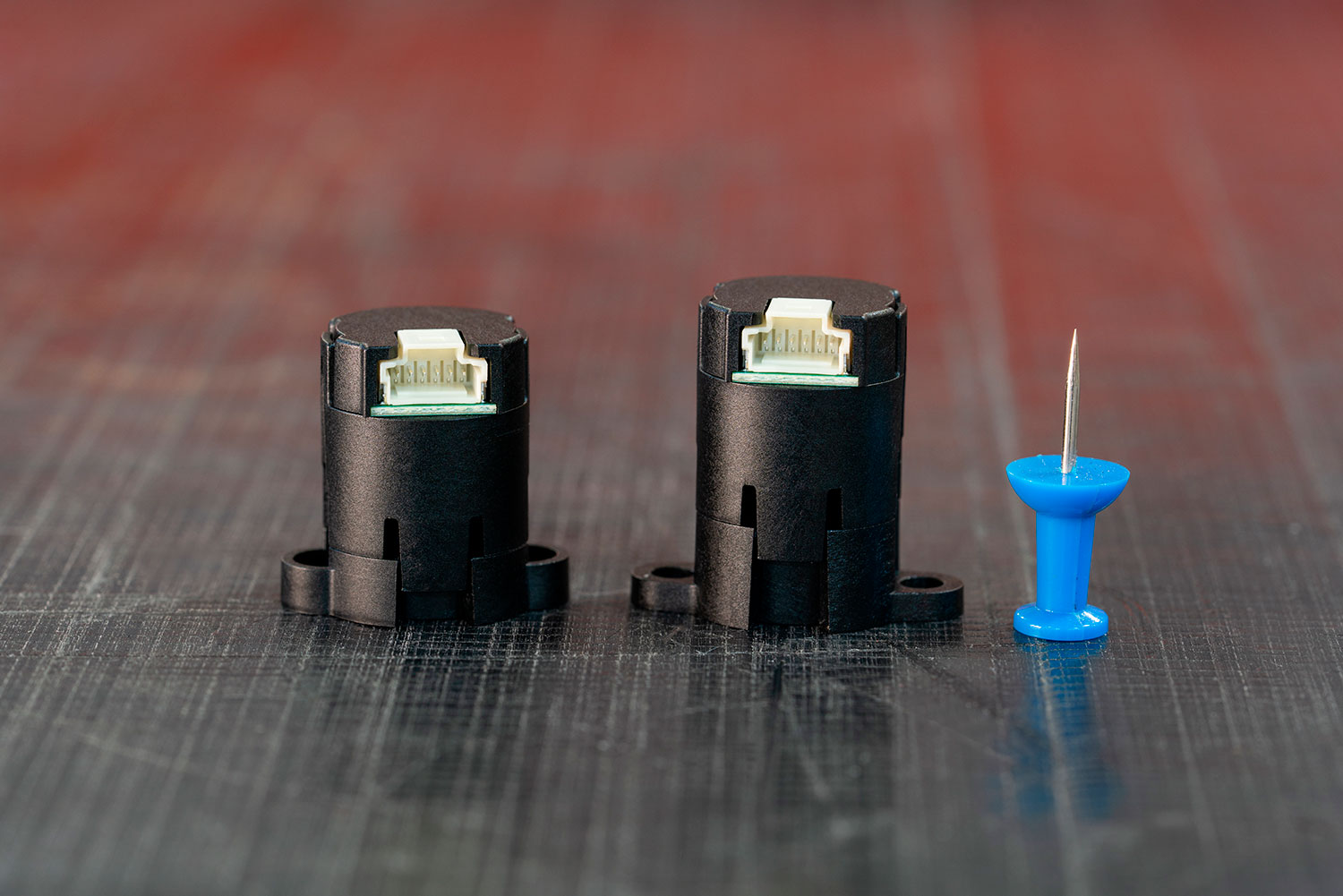

The new M3K Miniature Magnetic Encoder is available with incremental output or an incremental and 12-bit absolute output configuration. Read More »

Published 2/21/2021 in News > Press Releases

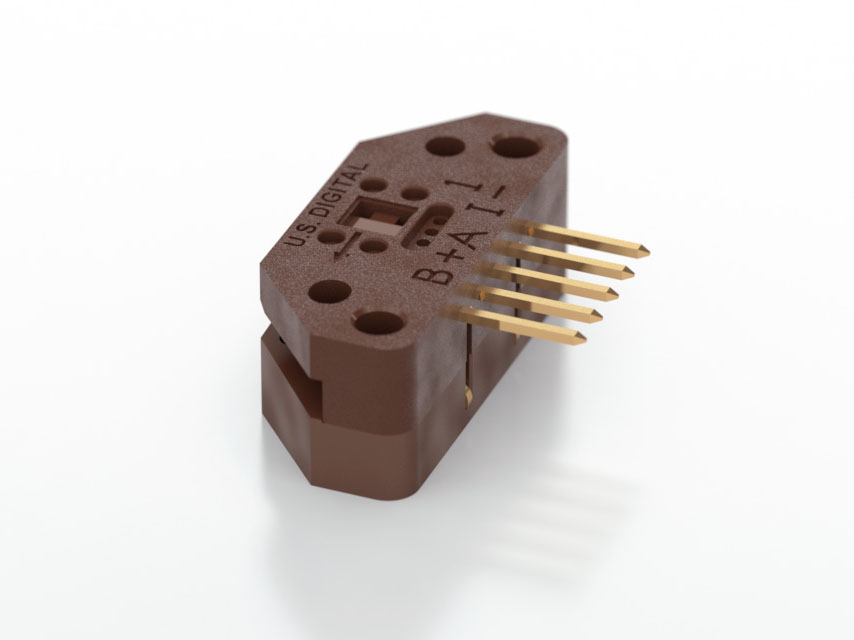

The new E16 Micro Optical Kit Encoder has a 10mm bolt circle, fits 1.5mm (0.059″) and 2mm (0.079″) shafts and provides A, B and Index digital quadrature signals. It comes in a variety of resolutions ranging from 250/256 to 4,000/4,096 CPR. Read More »

Published 9/16/2020 in News > Press Releases

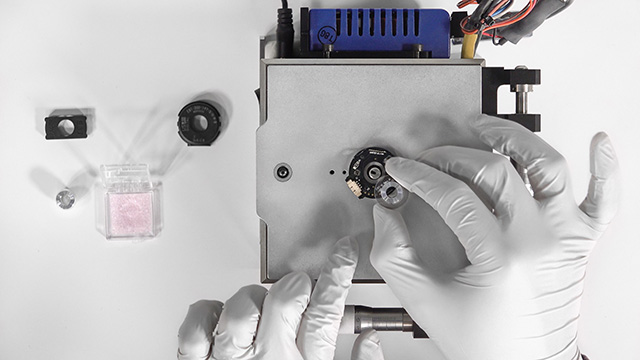

US Digital in May celebrated its 40th anniversary as a U.S. Manufacturer of optical encoders and other motion control components. Read More »

Published 5/26/2020 in News > Press Releases

US Digital on Tuesday announced that it is adding 800 CPR resolution to its EM1 transmissive optical encoder. Read More »

Published 3/18/2020 in News > Press Releases

US Digital on Tuesday announced that it is expanding its EC35 commutation encoder line with 3 new, higher resolutions, topping off at 60,000 CPR. The 3 new encoder configurations will make their official debut at SPS in Nuremberg, Germany. Read More »

Published 11/26/2019 in News > Press Releases

We've got some great news about our smallest encoders. The E4T and S4T miniature optical encoders are now available at even higher resolutions than before! With two new CPRs of 512 and 1000, we've successfully doubled the resolution while keeping the housing unchanged. Read More »

Published 11/13/2018 in News > Press Releases

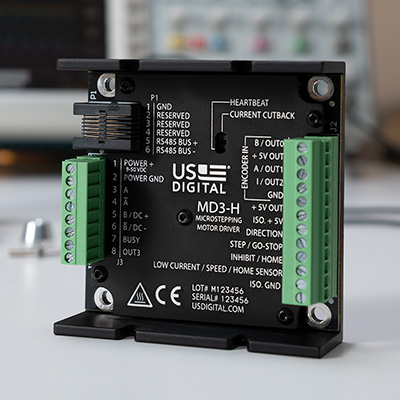

US Digital, a U.S. manufacturer of motion control products since 1980, announces the release of the MD3 Programmable Microstepping Motor Driver. It is capable of driving motors from NEMA size 14 to 42. The MD3 accepts 9-50VDC power inputs and rated for currents up to 7A continuous duty. Read More »

Published 8/6/2018 in News > Press Releases

Introducing PayLink from Nodus Technologies, Inc.. PayLink is a fast, secure, and convenient way for US Digital customers to make credit card payments 24 hours a day, seven days a week from anywhere! Read More »

Published 5/21/2018 in News > Press Releases

More in News

Company Links

- About Us

- Careers

- Contact Details

- Distributors

- Environmental Stewardship

- Legal

- Quality and Compliance

- Videos

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.