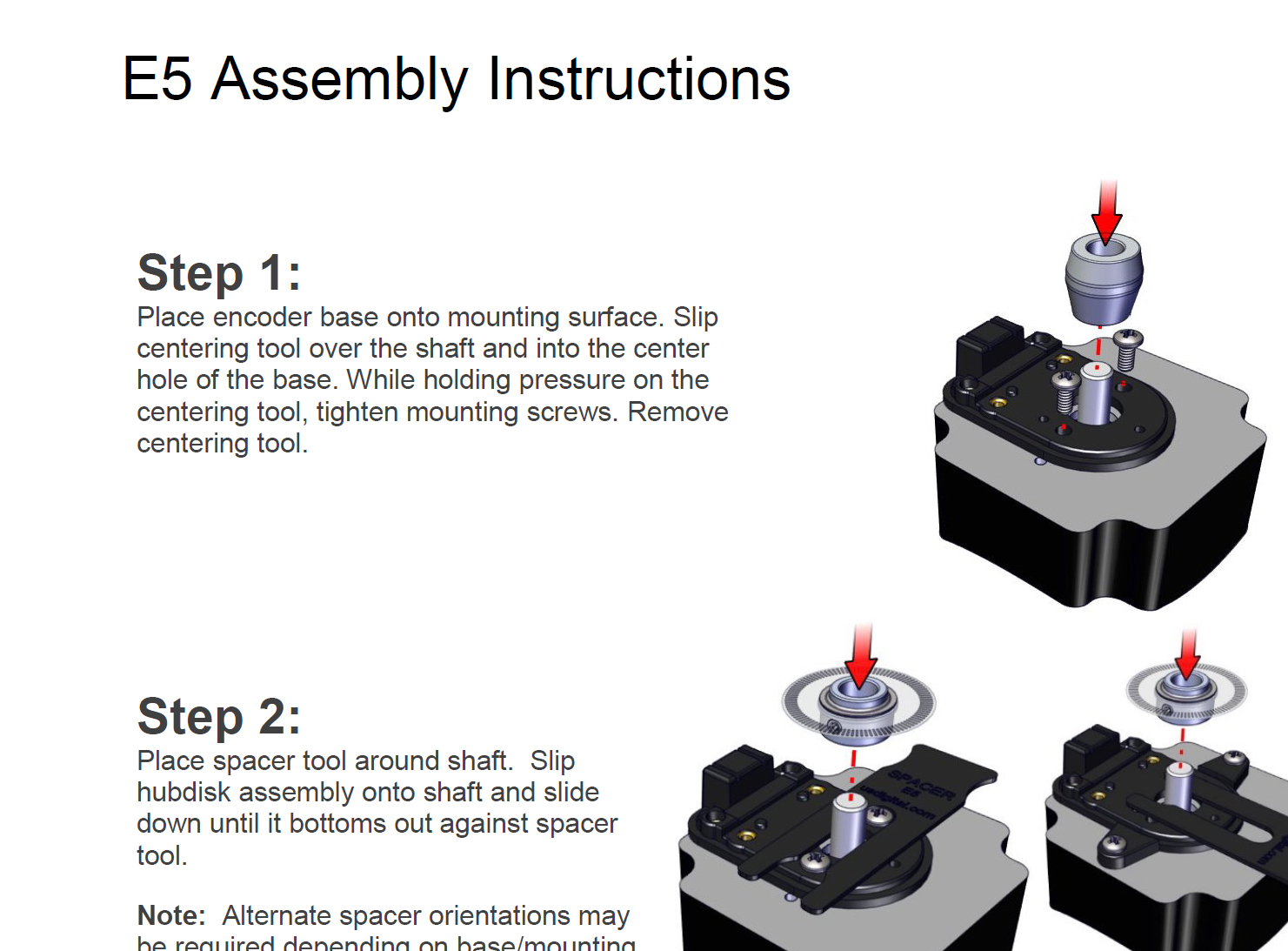

1. Centering Tool

Part #: CTOOL - (Shaft Diameter)

Description: This reusable tool provides a simple method for accurately centering the E5 base onto the shaft.

It is recommended for the following situations:

- When using mounting screws smaller than #4-40.

- When the position of the mounting holes is in question.

- When using the 3-hole mounting pattern.

- When using the T-option transfer adhesive.

Instructions: When mounting the encoder base, slide the centering tool down the shaft until it slips into the centering hole of the encoder base. Tighten mounting screws, then remove the centering tool.

2. Hex Tool

Depending on the order quantity and packaging option, either a hex driver or hex wrench is included.

Part #: HEXD-050

Description: Hex driver, 0.050" flat-to-flat for #3-48 or #4-48 set screws. Only included with -B or -1 packaging options.

Part #: HEXW-050

Description: Hex wrench, .050" flat-to-flat for #3-48 or #4-48 set screws. Only included with -2 or -3 packaging options.

3. Spacer Tool

A spacer tool is included for all packaging options.

Part #: SPACER-E5

4. Screws

Part #: SCREW-080-250-PH

Description: Pan Head, Philips #0-80 UNF x 1/4"

Use: Base Mounting

Quantity Required: 3

Screws are not included

Part #: SCREW-256-250-PH

Description: Pan Head, Philips #2-56 UNC x 1/4"

Use: Base Mounting

Quantity Required: 2

Screws are not included

Part #: SCREW-440-250-PH

Description: Pan Head, Philips #4-40 UNC x 1/4"

Use: Base Mounting

Quantity Required: 2

Screws are not included

Part #: SCREW-440-500-PH

Description: Pan Head, Phillips #4-40 UNC x 1/2"

Use: Module Mounting

Quantity Required: 2

Screws are included

Part #: SCREW-440-625-FH

Description: Flat Head, Phillips 4-40 UNC x 5/8"

Use: Cover Mounting

Quantity Required: 2

Screws are included

Part #: SCREW-448-063-SS

Description: Socket Head Set Screw, 4-48 UNC x 1/16"

Use: Hub/Disk Mounting for 5/16" - 10mm Bore

Quantity Required: 1

Screw is included

Part #: SCREW-448-125-SS

Description: Socket Head Set Screw, 4-48 UNC x 1/8"

Use: Hub/Disk Mounting for 2mm - 1/4" Bore

Quantity Required: 1

Screw is included